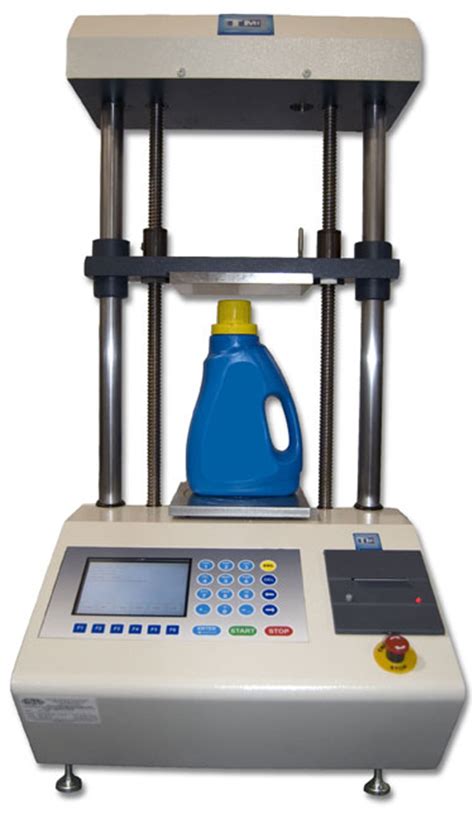

Bottle Vertical Compression Tester distribution|Top Load Compression Tester : dealer ISTA 3A: Package Integrity Testing of Product Packaging Less Than 150 lb. . A Caixa Econômica Federal sorteia na noite deste sábado (11/11), o concurso 2952 da Lotofácil. O sorteio é realizado no Espaço da Sorte, em São Paulo, e transmitido pelo .

{plog:ftitle_list}

Resultado da Best Japan AV porn site, free forever, high speed, no lag, over 100,000 videos, daily update, no ads while playing video. Videos. Recent update.

Vertical compression integrity testing specifies the resistance of a packaging to complete, filled transport packages. This package test method is also used to assess the performance of a .CONTACT US. Please send us a message or call us using the information below.. .

CONTACT US. Please send us a message or call us using the information below.. .ISTA 3A: Package Integrity Testing of Product Packaging Less Than 150 lb. .

ISTA Overview. ISTA package testing is the process of validating packages to .ISO 13355: Vertical Random Vibration Testing. ISO 13355 carries out vertical .Top-load strength is an excellent method to optimize the necessary force required to produce deformation and failure of bottles and containers. Top load strength can also identify thinned .Vertical Compression Test. This standard aims to determine the resistance of a plastic bottle to deformation during the filling and capping process, as well as its ability to withstand gross .

Vertical Compression Test. The Vertical Compression Test (VCT) may be used to objectively assess spinal stability and may accurately screen for individuals with postural instability.1 This test assesses the spine’s .

Compression testing is a mechanical procedure for determining how a test sample will react to a force being applied across one side of the test sample. A box compression testing machine applies the compressive force to the .

The vertical compression test is completed by either using a vertical compression machine in compliance with ASTM D642: Determining Compressive Resistance of Shipping Containers, Components and Unit Loads, or weights and a load spreader. The vertical compression test is carried out by positioning the product in its intended shipping orientation.Second, the test may be a part of a sequence to measure the ability of a package to the distribution system. As an ISTA and ISO 17025 certified lab, Keystone realizes the importance of vertical compression integrity testing. . Vertical compression testing allows for the assessment of pallets’ load-bearing capacity, ensuring they can .Bottle Perpendicularity Tester is a state-of-the-art device designed to ensure the precise perpendicularity of bottles. . Tablet Compression Tester; Vacutainer Drawing Volume Tester; Paper and Board Testers Menu Toggle. Puncture Tester; . The 1/2 of the difference between the two is the vertical axis deviation value. Technical Data.Testing vertical compression packages assesses the strength of a package under compressive force. It helps identify the package's ability to protect its contents during distribution and offers advantages such as cost-eff iciency, product launch assurance, customer satisfaction, and faster product to market. Two methods are used to test, involving a vertical compression machine .

Some materials, such as a PET bottle, distort during a compression test and are measured by the degree of distortion, whereas other materials such as ceramics fracture, produce a definitive compressive strength value. . Spring supports maintain vertical alignment of springs during compression testing, improving the level of safety for the .A box compression tester assesses the structural integrity of cardboard boxes by applying pressure until they deform. This test is crucial for understanding how boxes will perform under stacked conditions. Box Compression Tester (Digital Model) is used to evaluate the performance quality of packaging boxes. It calculates the amount of vertical compressive .The final thickness of the bottle is 0.96mm and stress distribution reduced to37.9Mpa as shown in fig 11. 3.4 Top Load Testing Top load test is widely utilized in the PET bottle industry. This test a look at reveals the stacking load-bearing capability .and failure of bottles and containers. Top load strength can also identify thinned areas in the wall of the bottle resulting in poor wallthickness distribution. Model 17-77 Compression Tester meets International Standards and Corporate testing methods for compression strength requirements for a variety of materials and products. A new enhanced

A plastic bottle perpendicularity test measures the vertical alignment of a bottle. This test determines if a bottle’s axis is perpendicular to its base, ensuring the bottle can stand straight without tilting. Proper vertical alignment is vital for automated filling lines and consumer satisfaction. Importance of the Plastic Bottle .The TopLoad Tester (TL2000) provides automatic measurement of the vertical strength of rigid containers, quickly and easily. The TL2000 can simulate typical loading conditions that occur during the filling/capping process and as a result of warehouse stacking. Features. Specifically designed for testing plastic bottlesCompression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized .

4.5 The following procedures are carried out according to the type and the purpose of the test: a) Pass test Increase the force applied to the specified value. When the specified value is achieved, the plates shall be withdrawn. After testing a predetermined number of . It simulates the pressure that a bottle cap may experience during transportation, storage, or use. The top load testing process involves applying a vertical force on the top of a bottle cap until it reaches its breaking point or a predefined load limit. . Compression Testing: In this method, a bottle cap or closure is placed between two . Test 2: 4 compression tests on an assembly of stacked bottles connected finish-to-finish between wooden plates (C5) Test 3: 4 compression tests on an assembly of stacked bottles connected bottom-to-bottom between .

The PET bottle perpendicularity test measures the deviation of a bottle’s vertical axis from its true perpendicular position. This is achieved using a precise probe that contacts the bottle at specific points, along with a rotating mechanism that ensures comprehensive measurement. Key Features of the PET Bottle Perpendicularity Testersubjected to real axial pressure when testing. Stable compression speed, . Test Item: Vertical Load of Glass Bottles. Description: VLT-100 Vertical Load Tester measures the vertical load strength of glass containers, simulating capping and stacking loads. Helps to reduce broken containers during capping and stacking.

Vertical Compression Testing

Vertical Compression Test

In this test, a bottle is loaded into a compression testing machine and a compression plate presses down on the neck of the bottle. Depending on the procedure, the machine can produce a target force and then stop, or produce an increasing force until the sample buckles. A minimum force is usually specified, and compared against the test result .

A top load test is a compression test on a product such as: drinks bottle, shampoo bottle, yogurt container, food tray, crate, etc. The axial force causes deformation of the product. Typically the test measures the maximum force to reach the yield point or a specified deflection distance. Common industry standard relating to this test are;IDM MTC-100 VERTICAL UNIVERSAL TENSILE TESTER Cod: 030101 Standard: None. The dynamometers or Universal Testing Machines have capacities of 1 kN to 5 kN (200 lbf or 1,000 lbf) and include two models. The S Series and the T Series. These machines have been designed to test a wide range of materials such as: plastics, films, paper, packaging materials, filter .

Top Load Compression Tester

Compression testing can occur hydraulically, pneumatically, or mechanically. The purpose of compression testing is to subject a package or container, whether filled or empty, to a fixed load. Stacking testing is carried out very similarly to compression testing. A predetermined load is maintained for a predetermined time or until collapse occurs.

We undertake vertical load testing (also known as head load, compression, and axial-load testing) using a compression tester to determine a product’s resistance to vertical load forces. This is commonly used to assess container glass packaging such as bottles, jars and vials – which undergo palletisation, capping or stacking. The compression tester scans an image of the particles scattered on a sample table and then records their positions. The image of each particle is also recorded in order to determine the particle size. The particles are then crushed individually. A schematic diagram of the robotic compression tester is shown in Fig. 3.Technical specifications: Measure range: 0 – 20000 N Units: KN / Kgf Resolution: 0.2N Power: 220 V, 50-60 Hz Weight: 150 kg Glass Bottle Top Load Tester – Maximum Top Load Resistance Tester for Glass Bottles ISO 8113:2004 Glass containers — Resistance to vertical load — Test method This standard was last reviewed and confirmed [.] The test distribution of the vertical horizontal stiffness offset from the NORM distribution significantly. Meanwhile, the test distribution fits the LOGN and GEV distribution well, therefore, the mechanical properties of the NRB bearing can be described using the GEV and LOGN distribution, as listed in Table 7.

web4 dias atrás · Safe to Download This APK com.applovin.array.apphub.tmobile_1.14.1-1014001_minAPI29(nodpi)_apkmirror.com.apk is signed by Sprint and upgrades your .

Bottle Vertical Compression Tester distribution|Top Load Compression Tester